When leather dries up, the fatliquor (fat, oil and water) transforms as gases or VOC (volatile organic compound) and diminishes through thin air.

This phenomenon results in surface shrinkage that appears as flattening of the quilting.

To restore or replenish the fatliquor the leather need to be relaxed and becomes puffy once again by the help of Hydrator-3.3. This is normally done with covering the leather with tissue towel as reservoir for leather to slowly hydrate, while it is put in a container or cling wrapper to prevent evaporation. This process may take up to 72 hours depending on the severity and absorbency of the leather. The hydrator helps to separate the stick together fibers so that the fatliquor can effectively coats them by hydrogen bonding.

Fatliquor immediately follow while the leather is hydrated and this is done at drying interval where the water goes out the fat and oil goes in. This is done until the leather is fully saturated.

The surface areas expand and the puffiness returns when the leather dries.

A fully fatliquor replenished leather retains up to 14% moisture level, even though the leather feels dry to the touch.

Similar to wooden floors that requires up to 10% moisture level, otherwise the crown or cup.

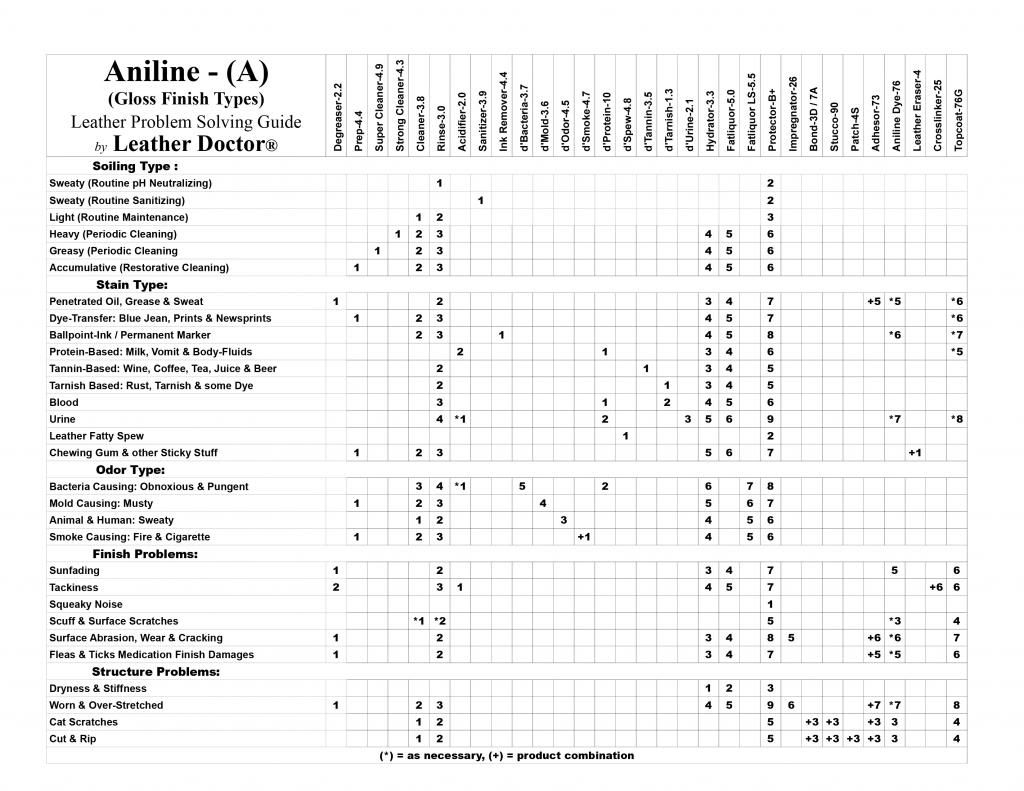

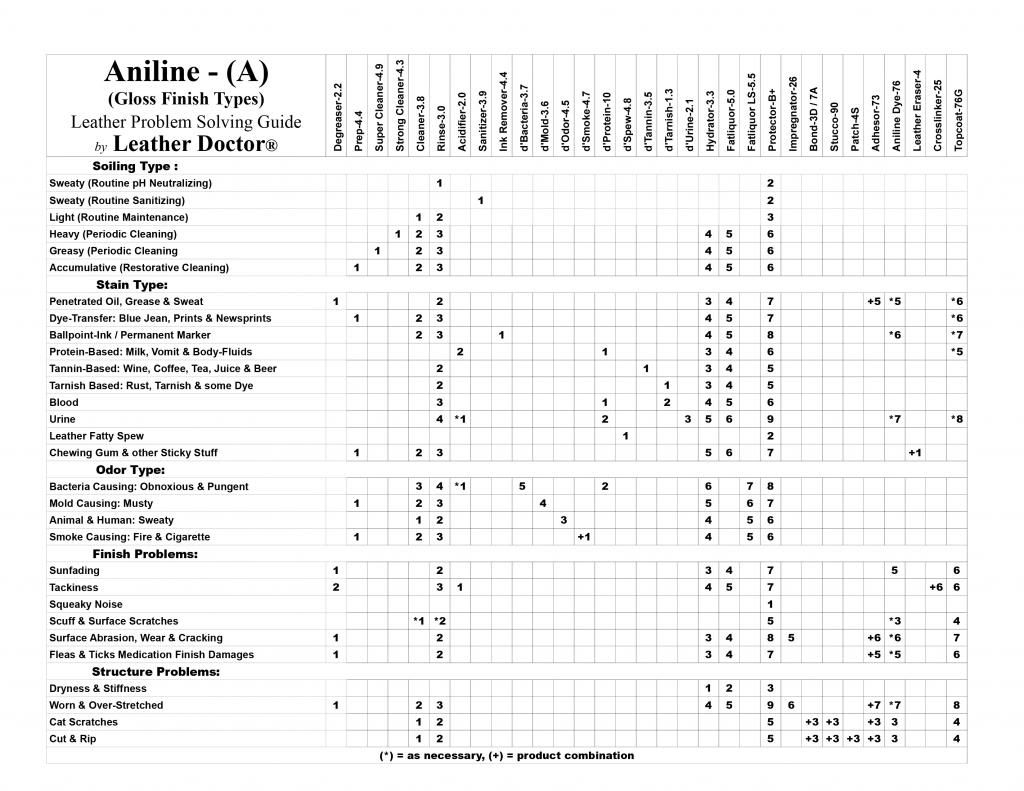

Use this Aniline leather Problem Solving Guide for further reference

Leather-Safe Problem Solving Guide (A) – Aniline Leathers

Products mention is found in this Kit A3

Leather Doctor® Kit A3 = Aniline Leather Care + Dye-Remover

2nd phase – Hydrating:

Hydrating process in the restorative cleaning system is done at an optimum level with moisture oozing out when press between finger and thumb. It would also require more dwelling time for the hydrator to do its work effectively. This is done with plastic cling wrapper to control evaporation for an overnight dwell. It’s to facilitate the working out of unnatural creases while the leather is fully relaxed. It’s to facilitate for an effective internal colloidal water movement to take effect; to suspend and wick foreign particulates to the surface to be towel extracted repeatedly while damp and erased when crispy dry. Advance technique is to cover the surface with absorbent tissue paper to trap foreign residue as it wicks through in the final drying process. The benefit of a longer dwell reduces contrast from UV fading as the dormant dyestuff is activated to surface. It also allows charging of the protein fibers below its iso-electric point positive, to effectively hydrogen-bond with the ionic negative charged fatliquor.

1] Spray Hydrator-3.3, spread with lint-free towel to plump the entire thickness of the leather, changing folding as it picks up soiling.

2] Advance technique uses absorbent tissue paper to lay over the entire surface, soak and free of air spaces as an extension of the surface.

3] This technique allows wicks up foreign soiling to be caught through by the tissue paper when it’s perfectly dry.

4] The crispy dried surface is further dry clean with Brush-1 and/or Eraser-4 to remove wicks up soiling particulates for inspection.

5] Repeat as necessary or proceed to fatliquoring.

3rd phase - Fatliquor Replenishing:

Fatliquor replenishing, besides the primary function of maintaining the leather for suppleness; is to contributes to the overall appearance in synergizing with the dyestuff to saturate a deeper color. Fatliquor diminishes through evaporation, that’s one reason manufacture label suggest to avoid direct sun and a distant from heat sources. Prolonged exposure with neglect will turn them cardboard stiff and when flex or pressure is put on them will crack. Fatliquor also diminishes through leaching from non leather-safe solution; the higher the pH above its isoelectric point the more severe it will be; often experience as stiffness when the leather is completely wet and dry again. Without the fatliquor to lubricate the fibers, they become stick together as the moisture wicks away. It is recommended to inspect the surface for an even appearance with Hydrator-3.3 prior to fatliquor replenishing it. This observation is to ensure that the surface is free of surface tension avoiding unnecessary blotchiness when dry.

Effective fatliquor is to saturate the leather structure in between water content evaporation and plumping it. Allow it natural dry for extra softness.

When dry thereafter, the leather fibrils will be well separated and lubricated to slide over one another smoothly during practical usage.

1] Spray Fatliquor-5.0, spread with lint-free towel for an even appearance and plumping it; changing folding as it picks up soiling.

2] Repeat application in between water contents evaporates until it’s saturated.

See this link on Kit A3

http://www.leathercleaningrestoratio...re-Dye-Remover

Whether you are a professional or novice, when instructions are followed result is achieved.

Puffiness is restored when shrinkage is rectified.

Roger Koh

[email protected]